If you can operate a machine, then you can run that pattern as easily as any embroidery design. “If you can digitise then you can produce a Venere pattern. One of the biggest advantages of this method is the fact that little or no extra skill is required, adds John-Paul. The Venere needles would then be used to cut out the circle.Īnother example where Venere needles come into their own is in the manufacture of badges, as illustrated here. The digitiser creates the stitches in the usual way, fi lling in the square except for the circle in the middle, which would have a border around the edge. To help understand this, picture a blouse that has a design that includes holes, such as a square block of stitches with a circle cut out in the middle. When this part of the design is reached, the needles will cut out the designated area, which may be within or without the pattern, depending on the desired effect.” There is no infi ll for this part of the design, just an edge or running stitch. “For these needles, the digitiser must create a vector that the machine can follow with the needles operating in a north, south, east, west (0°, 90°, 135°, 225°) cutting action.

For Venere embroidery this is still the case for the embroidered part of the design, but for the part of the design that is to be cut by the Venere needles, it makes more sense to think in terms of vectors or lines. This is used as a backdrop and the stitches are then digitised on top of this. “When digitising embroidery designs, the artwork is more often than not a bitmap image (the most common format is a jpeg).

It is now the digitising that takes centre stage. Once the needles have been inserted correctly into the machine, there is nothing else to do here. “For our purposes, let’s say that you have a 15-needle machine and are replacing needles 12, 13, 14 and 15 with the Venere needles. “It is important that the needle numbers are noted, as this will form part of the digitising,” explains John-Paul. Four of the Venere needles replace the same number of standard needles on the embroidery machine. Sold here in the UK through YES to work with its SWF embroidery machines, the Venere needle has no eye: instead, the tip of the needle has been reshaped with a cutting edge. “When used properly, this technique allows you to create stunning eff ects at a price not previously possible,” he adds. Instead, a special Venere cutting needle is used to cut out shapes in fabric.Ĭut-out embroidery may not be new, says John-Paul Burton, sales director at Your Embroidery Services (YES), but using Venere needles opens it up to a much wider market.

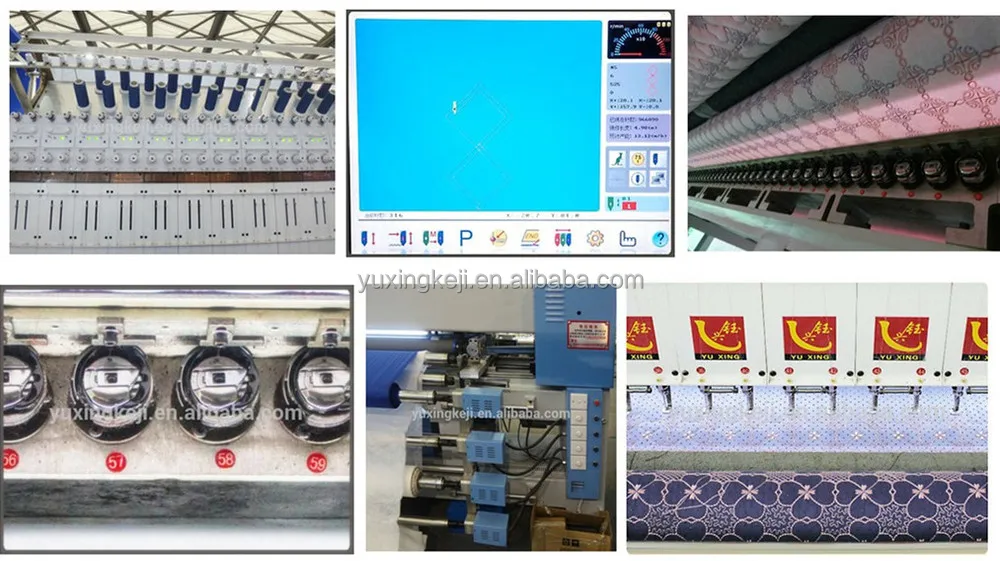

Guarantee of the various environment for embroidery operation by attaching SQ40i and ZD-10 devices.Since all new SWF machines are equipped with the Quick Change Cap System, getting a new SWF embroidery machine can help your company maintain its momentum between every job and maximize your business’s profits. Having to switch between caps and flat hoops is one of those things that can break the momentum. When you are pressed to get embroidery jobs done, nothing matters more than efficiency and maintaining the momentum of your workers. Both SWF 6 Head machines provide the same K-Series dependability and standard options. The UK also has a wider frame than the UH. The K-UK1506-45 has the 500mm Head Interval. The K-UH1506-45 has the 400mm Head Interval and is referred to as the Small Head Machine. SWF K-Series offers the K-UH1506-45 and the K-UK1506-45 Automatic Embroidery Machines. K-SERIES TUBULAR 6 HEADS (STANDARD SEWING FIELD)

0 kommentar(er)

0 kommentar(er)